Our strength lies in our profound understanding and application of a diverse range of chemical technologies and chemistries. We have an extensive portfolio of chemistries proven at lab scale, with over 30 successfully scaled to commercial production. Some of our specialized chemistries are:

Enzymatic (bio catalyst) chiral synthesis

- Aqueous-Based Process: Developed and optimized in aqueous media for environmentally conscious chemistry.

- Water Optimization & Recycling: Current processes are optimized for minimal water usage, achieving 90% water recycling.

- Pilot to Commercial Scalability: Water and solvent recycling protocols are established at pilot scale, with commercial scale implementation currently underway, demonstrating our commitment to sustainable manufacturing.

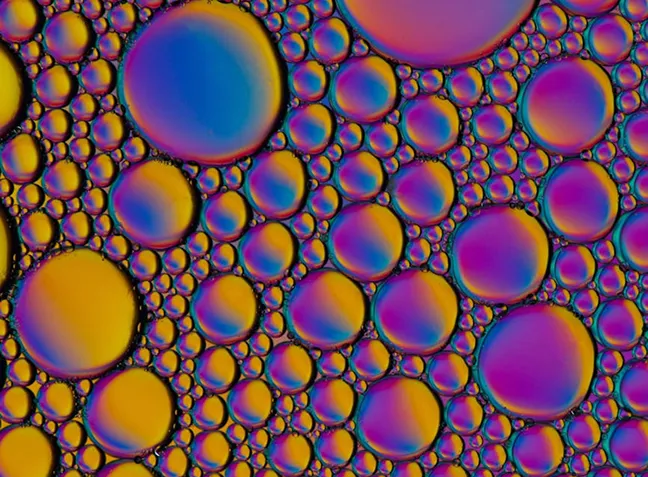

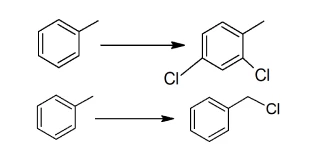

Photochlorination

- Proven Lab-Scale Expertise: Successfully demonstrated photochlorination reactions with diverse substrates, including aromatic and heterocyclic molecules in the lab.

- Pilot Scale Implementation Planned: Ready for scale-up, with pilot scale implementation currently planned, showcasing our commitment to advancing this technology.

Flow chemistry

- Diverse Reactor Portfolio: Equipped with a wide array of flow reactors including ACR/ATR, Vaportec, Corning, EnviFab, Zaiput, FlowRHEX®, and CSTR reactors, providing flexibility for different reaction requirements.

- Versatile Pumping Systems: Comprehensive pumping infrastructure capable of handling a variety of materials, including liquid-liquid and solid-liquid mixtures, ensuring seamless flow chemistry operations.

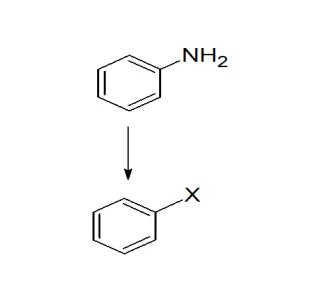

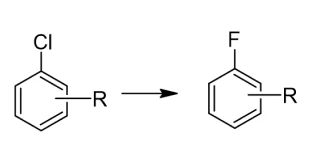

Fluorination (using anhydrous HF, KF, Balz-Schiemann reaction)

- Commercial Halex Reactions: Proven capability to perform Halex reactions at commercial scale, demonstrating our proficiency in this key fluorination technique.

- Exploration of Advanced Fluorinating Agents: Active exploration and development using solid-liquid phase fluorinating agents like KF and NaF, expanding our fluorination toolkit.

- Sustainable Practices: Water and solvent recycling established at pilot scale for fluorination processes, with commercial scale implementation in progress, reinforcing our commitment to environmental responsibility.

High pressure synthesis

- Multiple High-Pressure Reactors: Operating 6 high-pressure reactors constructed with both Stainless Steel (SS) and Hastelloy/Carbon steel (H/C) Materials of Construction (MoC), offering versatility for different chemical compatibilities.

- High Pressure Hydrogenation: Specialized for high-pressure hydrogenation reactions, a crucial capability for various chemical syntheses.

- Dedicated AHF Workstations: Two dedicated workstations for safely and effectively handling reactions with Anhydrous Hydrogen Fluoride (AHF).

- High-Throughput Catalyst Screening: Utilizing a high-pressure parallel synthesizer (Poly-block) for rapid catalyst screening and reaction condition optimization, accelerating process development.

- PLC Operated Systems: PLC operated for precise control and enhanced safety in high-pressure operations.

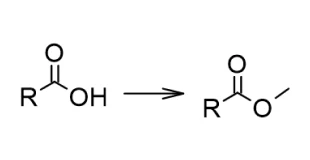

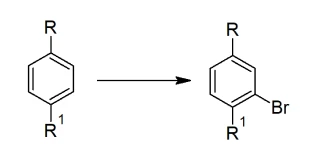

Other Chemistries

- Introduction of Chlorine

- Halex Reaction (using NaF, KF)

- Using HF

- Balz-Schiemann Reaction

- Using Bromine, Aqueous HBr, HBr in Acetic Acid