Strategically located in Rabale and Ankleshwar, India, our R&D centers are dedicated to advancing agrochemical process development, optimization, and seamless scale-up. We leverage cutting-edge technologies like continuous flow chemistry and catalytic asymmetric synthesis to accelerate route scouting, enhance yields, and deliver impactful solutions for our clients.

Our dedicated R&D centers

Synthesis Labs

- Number: Four dedicated synthesis labs.

- Fume hood capacity: 48 fume hoods ensuring safe and controlled experimental conditions.

- Key equipment & facilities:

- Rotary evaporators (Rotavapors)

- Combi Flash Chromatography Systems (Combi flashes)

- Preparative High-Performance Liquid Chromatography (Preparative HPLC)

- Precise Dosing Pumps

- Parallel Synthesizers for efficient reaction screening

- Laboratory Centrifuges

- Photochemical Reactors for light-sensitive reactions

- And more, supporting diverse synthetic methodologies.

Process Safety & Engineering Lab

- Purpose: Generate process safety information useful for hazard identification & risk assessment for a chemical process.

- Key equipment & facilities:

- Differential Scanning Calorimetry (DSC) for screening thermal hazards

- Accelerating Rate Calorimeter (ARC) to know safe and unsafe conditions of handling of thermally active chemicals.

- Reaction Calorimeter (RC) for understanding heat of reaction and desired level of process control requirement.

- Automated Jacketed Reactors for identifying standard operating conditions useful in designing process control

- Distillation Columns for fractionation of volatile components

- VLE Apparatus to determine VLE, useful in designing of distillation column

Kilo Labs

- Number: Two dedicated Kilo Labs (Herbicide & Non-Herbicide).

- Automation & Control: SCADA operated and automated systems with integrated data loggers for precise process control and data acquisition.

- Key equipment & facilities:

- Reactors in various sizes: 30L, 50L, and 100L capacity to accommodate different scale-up stages

- Packed Distillation Columns for efficient purification at larger scales

- Agitated Nutsche Filter Dryers (ANFDs) in Glass, Stainless Steel (SS), and Hastelloy/Carbon steel (H/C) for diverse material compatibility

- Centrifuge for solid-liquid separation

- Vacuum tray dryer

- Short Path Distillation Unit (SPDU)

- 20L Rotary Evaporator for solvent recovery at kilo scale

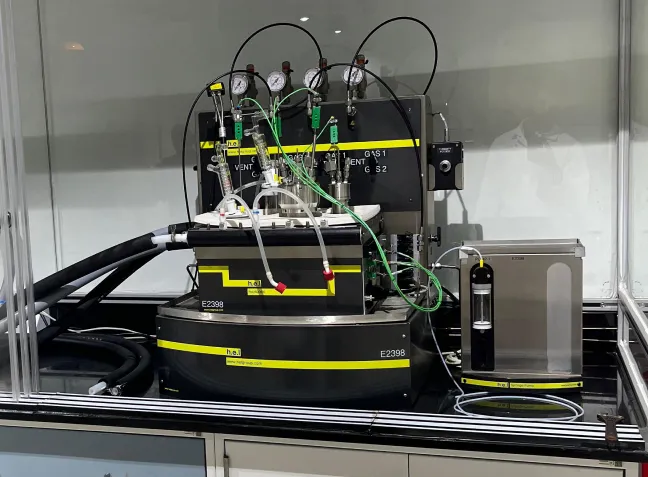

High Pressure

& Fluorination Lab

- Specialization: Dedicated to high-pressure and fluorination chemistry.

- High-Pressure reactor suite: 6 high-pressure reactors constructed with Stainless Steel (SS) and Hastelloy/Carbon steel (H/C) for material compatibility and safety.

- Capability for High-Pressure Hydrogenation.

- Dedicated AHF workstations: 2 dedicated workstations with specialized safety features for reactions involving Anhydrous Hydrogen Fluoride (AHF).

- High-Throughput screening: High-pressure parallel synthesizer (Poly-block) for rapid catalyst and reaction condition optimization.

- Control systems: PLC operated for precise control and enhanced safety in high-pressure and hazardous reactions.

Flow Chemistry Lab

- Purpose: Development of cost-effective processes through flow chemistry.

- Flow chemistry reactor portfolio (Current plan):

- Corning Silicon Carbide – G1 Reactor

- Vapourtech – R4 series reactor and photo reactor

- ACR-ATR-AM (Automated Continuous Reactor – Advanced Technology Reactor – Automated Modular) technology

- Continuous Stirred Tank Reactor (CSTR)

- Static Mixers for efficient mixing in continuous flow

- Membrane Separation technology for continuous separation and purification

Analytical Lab

- Purpose: Central analytical services for quality control, research support and data generation.

- Key equipment & facilities:

- High-Performance Liquid Chromatography (HPLC) and Gas Chromatography (GC) Systems

- Liquid Chromatography-Mass Spectrometry (LCMS) and Gas Chromatography-Mass Spectrometry-HeadSpace (GCMS-HS)

- Evaporative Light Scattering Detector (ELSD), Refractive Index (RI), and Fluorescence Detectors for HPLC

- Ultra-Performance Liquid Chromatography (UPLCs) for high-resolution and rapid analysis

- UV-Vis Spectrophotometer for spectroscopic analysis

- Infrared (IR) Spectroscope for molecular vibrational analysis

- Ion Chromatography for ionic species analysis

- Nuclear Magnetic Resonance (NMR) Spectrometer for detailed structural determination

- Inductively Coupled Plasma Mass Spectrometry (ICP-MS), Atomic Absorption Spectroscopy (AAS), and Ion Chromatography (IC) for elemental analysis

- Preparative High-Performance Liquid Chromatography (Preparative HPLC) for purification of analytical standards and small quantities of compounds.