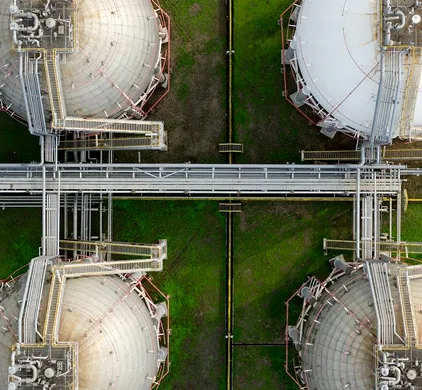

Cohizon Life Sciences has a robust and reliable manufacturing footprint, anchored by two state-of-the-art production units. With a combined capacity exceeding 15,000 TPA, we are equipped to handle large-scale chemical manufacturing demands. Each site operates with dedicated, self-sufficient infrastructure, including boilers, tank farms, waste treatment, and comprehensive storage facilities, ensuring seamless and dependable production.

Safety first, compliance always and environment forever

We strive to create a zero-harm workplace by creating a cultural transformation from reactive to interdependent and visible felt leadership.

Site 1

Advanced Infrastructure

The manufacturing site features dedicated multipurpose production lines that are DCS operated, supported by a Utility Block, Admin Block, and a Hydrogen Station. It includes an Incinerator, MEE Plant, a Dedicated ETP, Brine & Chilling Plant, and a Tank Farm, with facilities for hazardous waste storage and management.

Reaction scale

1-25 KL

5 RM & FG

warehouse

Total Reactor vol 2340 KL

>30 reaction capabilities

Land Area

71362 m²

35000 m²

Builtup Area

Key Highlights

Comprehensive on-site Equipment

Unit 1 is supported by a full suite of on-site equipment and utilities essential for efficient and sustainable operations, including:

Multipurpose Plants

Multipurpose plant- A

Multipurpose plant- B

Multipurpose plant- C

Multipurpose plant- D

Multipurpose plant- E

Multipurpose plant- A

9 products

4000 TPA capacity

4000 TPA capacity87 reactors (1090 KL)

DCS Operated

Multipurpose production lines

Reactions

Amidation CyclizationOxidative ChlorinationDiazotizationSulfonamide ReactionBrominationThiolationCondensation

Multipurpose plant- B

7 products

2800 TPA capacity

2800 TPA capacity58 reactors (680 KL)

DCS Operated

Multipurpose production lines

Reactions

Vilsmeier ReactionPhosphorylationFriedel-Crafts ReactionOxidationDry HCL GenerationDehalogenation

Multipurpose plant- C

5 products

5800 TPA capacity

5800 TPA capacity45 reactors (400 KL)

DCS Operated

Multipurpose production lines

Reactions

ChlorinationHigh Temp & Pressure MorphonolysisSelective ChlorinationStevens Rearrangement

Friedel-Crafts ReactionCondensationAmination Phosphorylation

Friedel-Crafts ReactionCondensationAmination Phosphorylation

Multipurpose plant- D

1 product

300 TPA capacity

300 TPA capacity9 reactors (130 KL)

DCS Operated

Multipurpose production lines

Reactions

ChlorinationCondensation

Multipurpose plant- E

3 products

300 TPA capacity

300 TPA capacity3 reactors (40 KL)

DCS Operated

Multipurpose production lines

Reactions

CondensationSolvent Recovery

Site 2

Advanced Multi-Purpose Plant with Expansion Potential

The site houses a DCS operated plant with dedicated infrastructure and utilities, enabling continuous chlorination and fluorination processes with precision and safety.

Capacity

1320 ΤΡΑ

Land Area

31384 m²

Key Highlights

Plants

Plant - 1

Plant - 2

New pilot plant

Plant - 3

Open land Area available

Plant - 1

Specialty intermediates plant

720 TPA capacity

720 TPA capacityGas Phase reactors

SS , MSGL reactors

Exotic MOCs incl. Inconel, Monel, Hastelloy etc.

Reactions

Continuous chlorination and fluorination at high temperature in gas phase fluidized bed reactor

High pressure hydrogenation

High pressure hydrogenation

Plant - 2

Specialty intermediates plant

600 TPA capacity

600 TPA capacityPlant Commissioned – April’25

Gas Phase reactors

SS , MSGL reactors

Exotic MOCs incl. Inconel, Monel, Hastelloy etc.

Reactions

Continuous chlorination and fluorination at high temperature in gas phase fluidized bed reactor

High pressure hydrogenation

High pressure hydrogenation

New pilot plant

Exp. Commissioning – June’ 25

14 reactors , 2 auto clave

Sizes from 0.5 Kl to 2 Kl

Structured / Random Packing distillation column

Solid Isolation (Centrifuge), Filtration

Drying (ANFD, RVPD)

Reactions

PhotochlorinationAHF based fluorinationHalogenation, Grignard , Hydrogenation etc

Plant - 3

Being a CDMO organisation we are always ready to service our customer’s need of commercial volumes at any point of time in a fastest time frame.

In view of this as a philosophy we always keep one plant Civil work completed till plinth area and keep it ready for any customer’s.

For MPP-3 in Unit-2, we have completed all civil work for approximately 2100 m² area. If any of our customer’s products mature to the point of taking up commercial production, we can build and prepare the facility for commercial production within 9-12 months, depending on the nature of the equipment and their delivery times.

Open land Area available

Unit-2 is our new unit that started about 3 years before. Apart from the above plants which we have already started, we have almost ~ 31384 m2 open land available for future expansion of new plants.